Experimenting doing nothing

Since I not able to do anything at the moment, I figured that I might as well tell you about what it is that I am actually doing (or supposed to do) at RMIT in Melbourne.

My research involves focussing an ion beam (beam of accelerated charged particles) by means of a very small hole, in general referred to as an aperture. Without the use of such an aperture the lower limit of a focussed beam spot is in the order of 500 nanometre. A nanometre is one millionth of a millimetre; by comparison a hair is typically 50 micrometers in diameter, which is one two hundredth of a millimetre. In other words, a very very very tiny spot. But we want to go to even smaller beam spots in order to make even smaller structures, up till structures of just a few atoms, or even single atoms implanted in some material.

My research involves focussing an ion beam (beam of accelerated charged particles) by means of a very small hole, in general referred to as an aperture. Without the use of such an aperture the lower limit of a focussed beam spot is in the order of 500 nanometre. A nanometre is one millionth of a millimetre; by comparison a hair is typically 50 micrometers in diameter, which is one two hundredth of a millimetre. In other words, a very very very tiny spot. But we want to go to even smaller beam spots in order to make even smaller structures, up till structures of just a few atoms, or even single atoms implanted in some material.

The reason for creating such small structures is to develop a new kind of computer, mostly referred to as quantum computer. I won’t go into detail here about how such a device is supposed to work, but I want to stress that the accurate control of structures and individual atoms on a very small scale is essential.

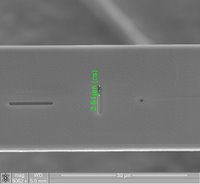

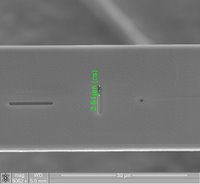

Designing the aperture is a challenge on its own, as it is quite difficult to manufacture a suitable ‘hole’. As basis I use a silicon cantilever (think of it as a very small silicon diving board) connected to some holder. With the use of a different kind of focussed ion beam (using heavier particles) I can drill holes and structures in the cantilever (see picture). During drilling I discovered that the cantilever is not as thick as I thought it would be, 3 micrometre in stead of the expected 15. As the ions that I’m using in the experiment need at least 7 micrometre of silicon to be stopped, this cantilever is useless for experiments.

Designing the aperture is a challenge on its own, as it is quite difficult to manufacture a suitable ‘hole’. As basis I use a silicon cantilever (think of it as a very small silicon diving board) connected to some holder. With the use of a different kind of focussed ion beam (using heavier particles) I can drill holes and structures in the cantilever (see picture). During drilling I discovered that the cantilever is not as thick as I thought it would be, 3 micrometre in stead of the expected 15. As the ions that I’m using in the experiment need at least 7 micrometre of silicon to be stopped, this cantilever is useless for experiments.

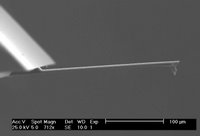

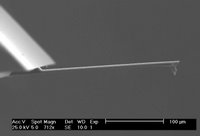

Nevertheless I decided to have a better look at the drilled cantilever in a machine called a scanning electron microscope (SEM). I wanted to see if the holes that I made in the cantilever were all the way through. Although it is not common to image cantilevers in a SEM, it has been done before. There was even a specially modified mounting probe available for this purpose. The mounting of the cantilever on the probe was successful (dropping it would quite possibly made the cantilever breaking off). Unfortunately the imaging itself was less successful and when we tried to get the probe out the SEM again, it appeared to be stuck. To summarize a long story: during the inserting of the probe the cantilever was smacked off the probe because with the holder of the cantilever stuck onto it, the probe was just a bit to high to enter the SEM properly. Conclusion: one day of work down the drain.

So you see, not everything is running smoothly at the moment.. I haven’t been able to conduct any experiments up till now, because of the reasons mentioned above. Hopefully I can drill some new thicker cantilevers tomorrow and conduct the first experiments later this week. I’ll keep you posted!

So you see, not everything is running smoothly at the moment.. I haven’t been able to conduct any experiments up till now, because of the reasons mentioned above. Hopefully I can drill some new thicker cantilevers tomorrow and conduct the first experiments later this week. I’ll keep you posted!

My research involves focussing an ion beam (beam of accelerated charged particles) by means of a very small hole, in general referred to as an aperture. Without the use of such an aperture the lower limit of a focussed beam spot is in the order of 500 nanometre. A nanometre is one millionth of a millimetre; by comparison a hair is typically 50 micrometers in diameter, which is one two hundredth of a millimetre. In other words, a very very very tiny spot. But we want to go to even smaller beam spots in order to make even smaller structures, up till structures of just a few atoms, or even single atoms implanted in some material.

My research involves focussing an ion beam (beam of accelerated charged particles) by means of a very small hole, in general referred to as an aperture. Without the use of such an aperture the lower limit of a focussed beam spot is in the order of 500 nanometre. A nanometre is one millionth of a millimetre; by comparison a hair is typically 50 micrometers in diameter, which is one two hundredth of a millimetre. In other words, a very very very tiny spot. But we want to go to even smaller beam spots in order to make even smaller structures, up till structures of just a few atoms, or even single atoms implanted in some material.The reason for creating such small structures is to develop a new kind of computer, mostly referred to as quantum computer. I won’t go into detail here about how such a device is supposed to work, but I want to stress that the accurate control of structures and individual atoms on a very small scale is essential.

Designing the aperture is a challenge on its own, as it is quite difficult to manufacture a suitable ‘hole’. As basis I use a silicon cantilever (think of it as a very small silicon diving board) connected to some holder. With the use of a different kind of focussed ion beam (using heavier particles) I can drill holes and structures in the cantilever (see picture). During drilling I discovered that the cantilever is not as thick as I thought it would be, 3 micrometre in stead of the expected 15. As the ions that I’m using in the experiment need at least 7 micrometre of silicon to be stopped, this cantilever is useless for experiments.

Designing the aperture is a challenge on its own, as it is quite difficult to manufacture a suitable ‘hole’. As basis I use a silicon cantilever (think of it as a very small silicon diving board) connected to some holder. With the use of a different kind of focussed ion beam (using heavier particles) I can drill holes and structures in the cantilever (see picture). During drilling I discovered that the cantilever is not as thick as I thought it would be, 3 micrometre in stead of the expected 15. As the ions that I’m using in the experiment need at least 7 micrometre of silicon to be stopped, this cantilever is useless for experiments.Nevertheless I decided to have a better look at the drilled cantilever in a machine called a scanning electron microscope (SEM). I wanted to see if the holes that I made in the cantilever were all the way through. Although it is not common to image cantilevers in a SEM, it has been done before. There was even a specially modified mounting probe available for this purpose. The mounting of the cantilever on the probe was successful (dropping it would quite possibly made the cantilever breaking off). Unfortunately the imaging itself was less successful and when we tried to get the probe out the SEM again, it appeared to be stuck. To summarize a long story: during the inserting of the probe the cantilever was smacked off the probe because with the holder of the cantilever stuck onto it, the probe was just a bit to high to enter the SEM properly. Conclusion: one day of work down the drain.

So you see, not everything is running smoothly at the moment.. I haven’t been able to conduct any experiments up till now, because of the reasons mentioned above. Hopefully I can drill some new thicker cantilevers tomorrow and conduct the first experiments later this week. I’ll keep you posted!

So you see, not everything is running smoothly at the moment.. I haven’t been able to conduct any experiments up till now, because of the reasons mentioned above. Hopefully I can drill some new thicker cantilevers tomorrow and conduct the first experiments later this week. I’ll keep you posted!

0 Comments:

Post a Comment

<< Home